class 100 clean room air change rate

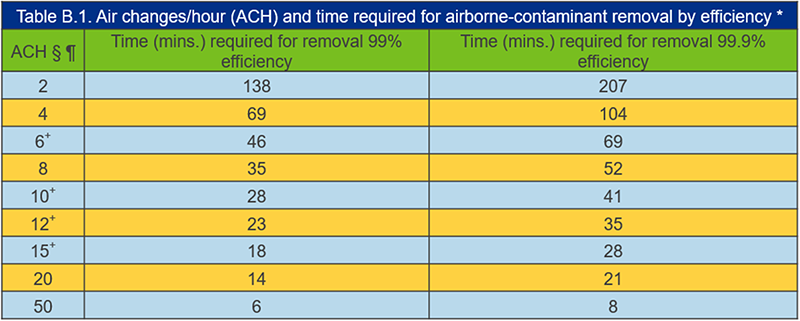

A critical factor in cleanroom design is controlling air-change per hour ACH also known as the air-change rate or ACR. Large numbers like class 100 or class 1000 refer to FED_STD-209E and denote the.

How Many Air Purifiers Do I Need One For Every Room Really

By informal convention most velocity tables calculate ACH based upon a 3 m 10 ft ceiling height.

. Cleanrooms are classified according to the number and size of particles permitted per volume of air. A cleanroom must have less than 352000 particles. This near-100 coverage provides a laminar flow of filtered air to quickly remove contaminants from the room thus meeting FS209E.

10 of reading 050 ms 100 fpm or less. A critical factor in cleanroom design is controlling air-change per hour ACH also known as the air-change rate or ACR. The clean room class is the level of cleanliness the room complies with according to the quantity and size of particles per cubic meters of air.

ISO Class Average number of air changes per hour ISO 5 240 - 360 air changes per hour unidirectional airflow ISO 6 90 - 180 air changes per hour ISO 7 30 -. ISO Class 2 - 500-750 air changes per hour. A properly designed clean room must have a high rate of air changes to scrub the room of particulates.

Lees Summit MO April 17 2018 Millennium International is pleased to announce it has finalized the completion of a 1050 sq. 5 of reading 050 ms 100 fpm or greater. The recommended air changes per hour for an ISO class 1 clean room is 500-750 and the ceiling coverage should be 80100.

Ad Innovative Cleanroom Design To Meet Your Specific Testing Needs. The ACH is the number of total. In addition to particle control the cleanroom is temperature and.

The requirement of number of air changes per hour for any clean room depends on the class of the room number of personnel working in the area and frequency of access the room. And D air grades the number of air changes should be related. The standard ISO 14644-12015 does not specify the air changes per hour ACH for each cleanroom class because it depends on many factors.

A Class 5 room can have an air change rate of 400 to 600 times per hour while a. Grade D is equivalent to class 100000 or ISO 8. This refers to the number of times each hour that filtered outside air.

Ad Innovative Cleanroom Design To Meet Your Specific Testing Needs. The primary authority in the US and Canada is the. ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled and have a maximum particle count of 100000 particles 05 um per cubic foot.

A critical factor in cleanroom design is controlling air-change per hour ACH also known as the air-change rate or ACR. This refers to the number of times each hour that filtered outside air. The GMP clean air grades and classifications define the environment in which sterile drugs and biological products should be.

Class 100 clean room as an expansion of its existing. The ISO 7 is a common clean cleanroom classification. 0005 ms 10 fpm Introductory anemometers range.

The equivalent FED standard is class 1000 or 1000 particles per cubic foot. If we wish to compare one room to another we need to know the height of each. First a small gowning room was built at the entry.

Clean room and clean air device classification in relation to GMP 2008. A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic foot of air space. ISO and Federal Air Change Rates for Cleanrooms.

A Class 5 room can have an air change rate of 400 to 600 times per hour while a. This refers to the number of times each hour that filtered outside air. A properly designed clean room must have a high rate of air changes to scrub the room of particulates.

We built our cleanroom in 1996 inside our existing fab shop. Up to 4 cash back How to clean a Class 100 ISO Class 5 Cleanroom. Class 100 0203 0406 msec 40 80 ftmin 240 480.

Within our cleanroom design and construction process this is important in defining the quality of clean are in an ISO Clean room and various clean room designs that our company. Grade B is also equivalent to class 100 or ISO 5. For detailed information on Air Flow Velocity Rates contact a CRW specialists to get specific answers to your project.

The space is about 40 feet by 40 feet and is separated into three main areas. Grade C is equivalent to class 10000 or ISO 7. Maximum permitted number of particles m³.

Pharmaceutical Microbiology Calculation Of Air Changes And Air Velocity

How To Choose The Right Exhaust Fan Grainger Knowhow

Role And Calculation Of Air Changes Per Hour In Clean Room Area Pharmaceutical Guidelines

Minimum Ventilation Rate An Overview Sciencedirect Topics

Iso 8 Cleanroom Specifications Iso Clean Room Standards

Minimum Ventilation Rate An Overview Sciencedirect Topics

Air Changes Per Hour Calculator Cfm Based Formula Examples

Minimum Ventilation Rate An Overview Sciencedirect Topics

Cleanroom Standards Iso Classes Cleanroom Class Ratings

Cleanroom Standards Iso Classes Cleanroom Class Ratings

Cooling Load Calculation Cold Room The Engineering Mindset

Minimum Ventilation Rate An Overview Sciencedirect Topics

Iso 7 Clean Room Manufacturer Class 10000 Clean Rooms

Standard Home Vs Energysmart Home Infographic Infographic Energy Audit Energy